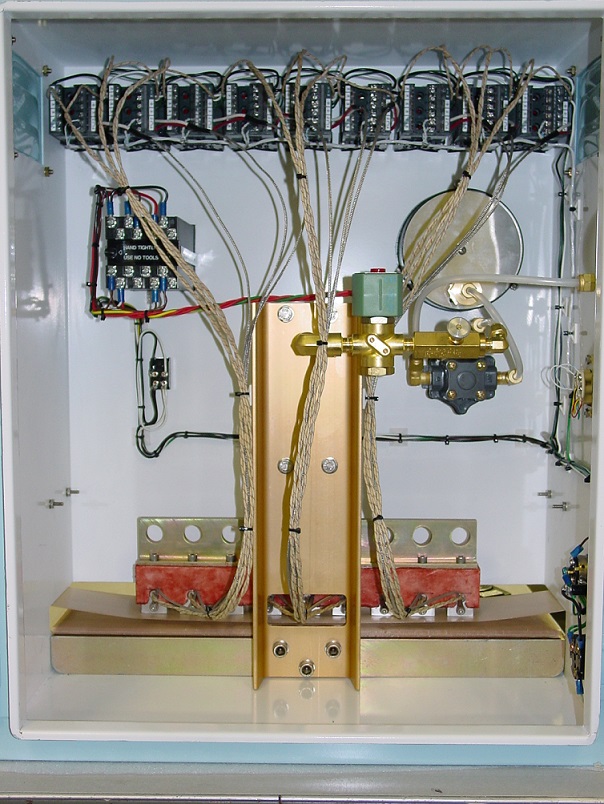

| The HST-09 Heat Seal Test Unit (Fig. 1) uses selectable times, pressures and temperatures to determine the best sealing characteristics of two plastic film samples. The unit consists of nine individual platens mounted on a common, movable bar. The bar is lowered by a spring-foot switch, the automatic reset timer energizes the solenoid valve for precise bonding times. Pressure against the film samples is indicated on an air pressure gauge and adjusted by an air pressure regulator. Each platen temperature is selected by a three digit, digital read-out set point and controlled by a sub-miniature plug in temperature control modules mounted inside the HST-09. A ten point selectable temperature indicator provides an accurate temperature reading of each zone in degrees F or C. The Teflon covered silicon rubber pad on the platen base, and the Teflon ribbon cloth under the platen zones, allow film samples to be inserted and removed easily. The four receptacles on the left side of the HST-09 permit connecting input power, clean air supply, foot switch control and a remote thermocouple. The HST-09 is protected by a fuse also located on the side of the unit. |  |

|

To operate, the controls are set for a specific time and air pressure. Next, the temperature controls of each heated zone are adjusted. A double sheet of plastic film then is inserted between Teflon ribbon cloth under the heated zones and the Teflon covered silicon rubber pad on top of the platen base. The zones are lowered by depressing the foot switch. After the desired time has elapsed, the heated zones automatically raise, allowing the sample to be removed and examined for the best sealing temperature points. For additional information regarding build times and pricing, please contact our office. |

|